How do Hamilton hot water storage tanks work?

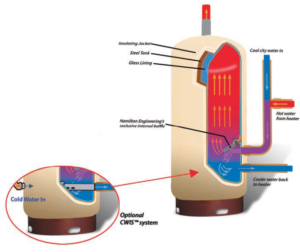

- As much as 80% of stored water is at target temperature during peak draw.

- No turbulent mixing of water. Cooler water stays at the bottom.

- Replaceable anode rods used to maximize tank life.

- Temperature and pressure relief valves for safe operation.

- For condensing water heaters, add our Cold Water Injection System™ (CWIS) to maximize heater condensing efficiency by directing coldest water to the water heater.

- 100% usable tank volume, allowing the use of a smaller tank.

-

80-200 GALLON MODELS

- All models are glass-lined and jacketed.

- Two inches of foam insulation is injected between the tank and outer jacket.

- Rated for 150 PSI working pressure; ASME certification is standard on all models above 120 gallons and optional on 120 gallons and below.

- 80 and 120 gallon models available as 316 T stainless steel tanks with two inches of foam insulation with jacket, rated for 125 PSI working pressure.

-

220-5000 GALLON MODELS

- Glass lining is standard; stainless steel, epoxy and cement linings optional.

- Standard working pressure of 125 PSI, 150 PSI optional.

- ASME stamped and certified.

- Designed to be installed vertically using the base ring supplied, or horizontally with optional mounting saddles.

- Various insulation jackets available, including microfoil blanket, 2″ foam with metal jacket.

- Lifting lugs supplied for ease of rigging and handling.