Standard features. Exceptional performance.

Whatever your budget or footprint requirements are, Hamilton has a system that will work for you. Efficiencies of our Copper Finned Tube units range from 81% to 88% (non- or near-condensing) and 96% (condensing), using an integrated secondary heat exchanger. Designs encompass conventional, atmospheric-fired, and pressurized combustion methods, with the latter available in both horizontal and vertical styles. Inputs range from 100 to 4000 MBH.

COPPER FINNED STANDARD FEATURES:

- Modular construction facilitates serviceability

- Factory fired and tested

- Five-year heat exchanger warranty (heaters)

- Ten-year heater exchanger warranty (boilers)

- Mounted ASME relief valve

- Stainless steel burners

- Compact design

- Mounted & wired flow switch

- Glass-lined andbronze headers (heaters)

- Cast iron headers (boilers)

- Spark ignition

- FM/CSD-1 gas train compliant (subject to codes)

-

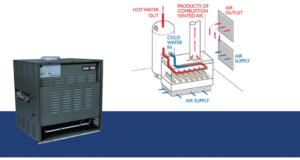

Pressurized Combustion

From 225,000 BTU to 2,300,000 BTU, and up to 85% efficiency.

Pressurized combustion minimizes the effects of combustion room variables from the air-gas mixing process. One or more internal fans, inside of a combustion chamber and sealed from the local environment, are utilized to create a pressure slightly higher than the surrounding atmosphere, resulting in an air and gas mix that is completely controlled.

Like atmospheric models, pressurized combustion models rely on adequate combustion and ventilation air to be provided through properly sized openings in the wall to the outside of the building. In our pressurized design, the process of combustion is independent from localized atmospheric conditions, achieving steadier efficiency and lower levels of emissions.

Pressurized combustion units have the standard features listed, as well as these additional parts:

HAMILTON 85—Up to 85% efficient:

- 500–1950 MBH

- Low NOx

- Ultra-compact footprint

- Stainless steel combustion chamber

- 2-stage firing

- UV flame detection

- Self-diagnostic control

MULTI-TUBE II—Up to 82% efficient:

- 225–2300 MBH

- Low NOx

- Field reversible headers

- Stackable frame

- Barometric damper (Category 1)

- Slide out heat exchanger

- Vertical or thru-wall venting

-

SEALED COMBUSTION

From 300,000 BTU to 4,000,000 BTU, and up to 98% efficiency.

Pressurized sealed combustion uses an inlet air connection to draw outdoor air directly to the combustion chamber, resulting in a balanced pressure on the exhaust and air inlet. This eliminates combustion and operational problems resulting from inadequate combustion and ventilation air.

Because no openings to the outside are required, additional energy is conserved in heating and cooling of the building. Our 88% and above efficient, sealed combustion units are typically microprocessor controlled, with features such as staged firing, to further promote an efficient use of fuel.

Sealed combustion units can also be installed outdoors, and have these additional features:

HAMILTON 96—Up to 98% efficient:

- 500–4000 MBH

- Condensing style heater

- Flame safeguard

- Modulating temperature control mixing valve

- Integral primary pump

- Full modulation with 4:1 turndown

- Low NOx

- HeatNet integrated boiler platform

- Linked operating control system for multiple unit applications

HAMILTON 88 XL—Up to 88% efficient:

- 2500–4000 MBH

- Low NOx

- Full modulation with 5:1 turndown

- HeatNet integrated boiler platform

- Variable speed blower

- Symmetrically air/fuel coupled

- Flame safeguard control with UV flame detection

HAMILTON 88—Up to 88% efficient:

- 500–2000 MBH

- Low NOx

- Full modulation with 5:1 turndown

- HeatNet integrated boiler platform

- Variable speed blower

- Symmetrically air/fuel coupled

- Flame safeguard control with UV flame detection

V-TUBE—Up to 85% efficient:

- 300–2100 MBH

- LED diagnostic panel

- 2-stage firing

- Field reversible headers

- Slide out heat exchanger

- Low NOx

- Full modulation with 5:1 turndown

- Stackable frame

- Pump delay control

-

Atmospheric Combustion

From 100,000 BTU to 399,999 BTU, and up to 83% efficiency

Heaters utilizing atmospheric combustion are designed so that the combustion chamber is open to the atmosphere, drawing in combustion air from the openings in the room, connected on the outside of the building. There are no internal controls to compensate for changes in the air supply.

Many variables such as barometric pressure, wind conditions or even open versus shut doors and windows, have an effect on the burner’s efficiency and quantity of emissions into the environment, so the selection of this design should take that into account. Each of our atmospheric combustion models have inlet & outlet thermometers, built-in draft diverters, and the options for a cupro-nickel heat exchanger and low water cut off.